Methanation

BIOGAZ Project

Power to gas - Power to methane.

The thermochemical recovery of CO2 today is one of the pivotal aspects of the energy transition. Indeed, the latter allows both to considerably reduce CO2 emissions from various industrial sectors and to store in chemical form the surplus electricity that can be produced by ENR. This makes it possible to respond to the time profile of demand and fluctuations in the source (peak).Our products: Catalytic Methanation Reactors

- Small demonstrators: CH4 flow rate produces ≤ 2 Nm3/h (Photos Minerve reactor)

- Industrial modules: Top Industrie is participating in the implementation of projects aiming at the development of industrial catalytic methanation modules characterized, in the long term, by CH4 product flow rates ≥ 100 Nm3/h.

Our goal : to develop plug and play solutions that can treat CO2 from different industrial environments.

Minerve project Power to Gas

Methanation, a process that converts hydrogen from renewable electricity by electrolysis into synthetic methane by reaction with CO2 on a catalyst, is a promising solution ... and already operational in Germany with the 6 MWe AUDI site. In this context, and in its vision of experimenting with the transitions to be made, AFUL Chantrerie has initiated a power-to-gas demonstrator called MINERVE, on the Chantrerie site.- First phase : Studies September 2014 to May 2015, technical, economic and regulatory study conducted by INDDIGO, SOLAGRO and BELENN. Cofinanced by ADEME, AFUL Chantrerie, ENGIE - Cofely, Department 44, with the support of BE CLIMAT (voluntary technical assistance from AFUL Chantrerie).

- Second phase : : Consultation September 2015 to September 2016, competitive dialogue, procurement to TOP INDUSTRIE associated with ENOSIS

- Third phase : Works October 2016 to January 2018, design, production of the demonstrator and commissioning on site.

- Fourth phase : Inauguration in September 2018, validation, process optimization and production during 2019 and 2020.

The electrolyser converts grid electricity into hydrogen by electrolysis of water. The selected electrolyzer is a PEM (proton exchange membrane) electrolyzer. PEM technology divides pure water into hydrogen and oxygen by applying a DC voltage.

The hydrogen produced is then stored in 4 bottles of 50L at 200 bar, i.e. an effective storage volume of 37 Nm3. This storage allows the methanation reactor to operate in nominal mode for more than 15 hours without the electrolyser being started up.

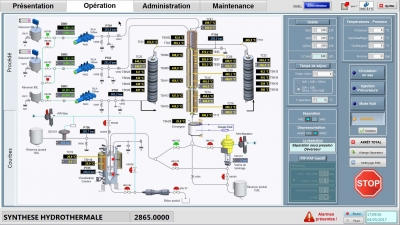

By the methanation reaction, hydrogen and CO2 are converted into synthetic methane in the methanation reactor (0.57 Nm3/h with a consumption of 2.37 Nm3/h of H2 and 0.6 Nm3/h of CO2) which can itself be stored in 8 bottles (capacity of 74Nm3).

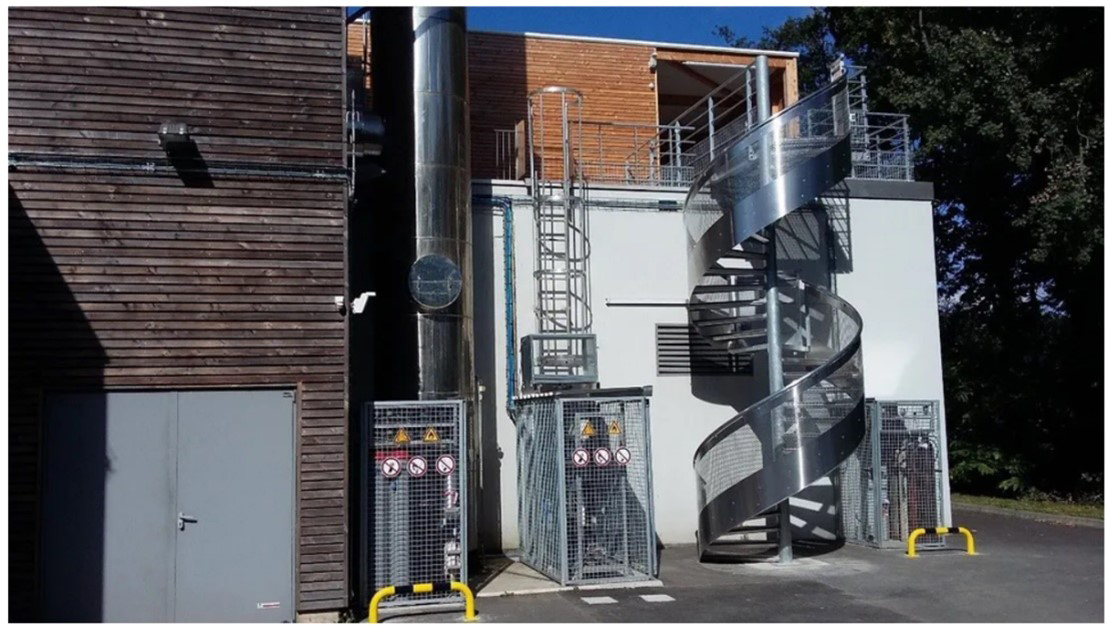

The methanation reactor developed by Top Industrie is a fixed bed reactor with electric gas heating and vortex cooling. These devices are less constraining and less dangerous than the classical oil bath devices. The unit is composed of 2 reactors in series in order to obtain the quality of methane compatible with CNG mobility. The installation of the platform is carried out on the roof of the gas boiler room, the H2 storage is located at the foot of the building with the C02 storage. The CNG station is located a few meters away.

They trust us