In addition to high safety and quality standards, we also provide assistance for the definition of the equipment for your supercritical fluid. Our rigorous project management system allows for On-time delivery. The customer can follow all the construction process, and be fully involved in the project during the installation and the training.

From the beginning of your project Top Industrie analyses the processes, the means, the sizing, and the cost impacts to give you the most relevant answer to the definition and particularly the realization of the equipment you require.

The key to your success is because Top Industrie listens to and understands your specific need and proposes the most suitable solution. From the research and development unit for the study of new processes, to the optimization of existing processes, to the pilot of large volume industrial production, we assist you in all phases of your project, from the initial sketch to the whole installation on your site.

With the scientific and technical support of specialized consultants if necessary, we will integrate all your specific environmental elements, standards and compliance (Atex, GMP...)

Why use supercritical fluids ?

There is also a temperature/pressure couple where the liquid and the gas phases have the same density, this is the critical point. Beyond this point, the fluid is said to be " supercritical ». At this stage only one phase exists. There is no state change between the liquid and gas phases, the transition is continuous and homogenous.

The fluid will be neither a gas nor a liquid but will possess the properties of both phases.

- No toxicity, non-flammable, cheaper, ˝Green solvent˝

- Easier recycling and reuse of supercritical solvent.

- A diffuseness greater than the liquid phase that allows better penetration into a porous environment.

- A viscosity similar to the gas that promotes the transfer of materials.

- A density close to the liquid, thus a strong power of solvation.

- A simple process based on the coupling of pressures and temperatures.

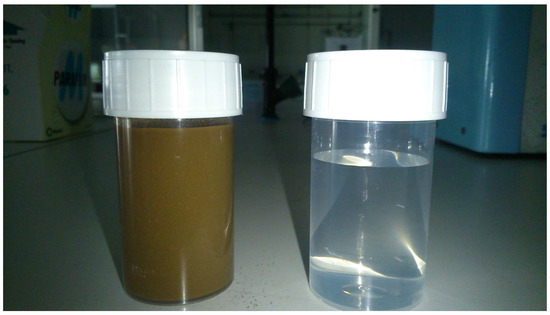

- Improved product performance and purity.

- Sustainable alternative to conventional production methods.

The use of co solvents such as methanol or ethanol improves the extraction or splitting process.

We will not detail here the usual generalities of the basic principles and the phase diagrams of Scf CO2, you will be able to find all this information on the website of our preferred partner : Supercritical Fluids

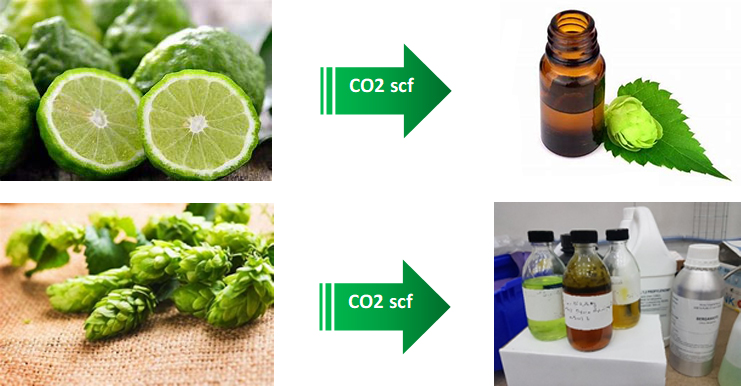

Extraction (SFE)

Fractionation (SFF)

Rapid Expansion (RESS)

Atomization PGSS

Grafting, Coating RESS / SAS

Cleaning, Degreasing

Purification

Polymerization

Water in the Sub-critical phase (pressure: 15 to 100 bars, temperature: 150 to 300 degrees Celsius) can solubilize hydrophobic compounds. Therefore, it can be used for the extraction of plant materials (polyphenols, tannins, terpenes...).

The oxidation in sub-critical water can also be carried out in order to obtain an effective treatment of waste. In this case, the process is called wet air oxidation (WAO).

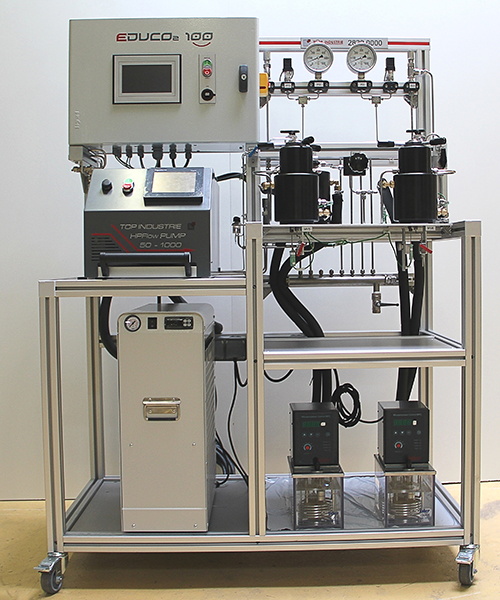

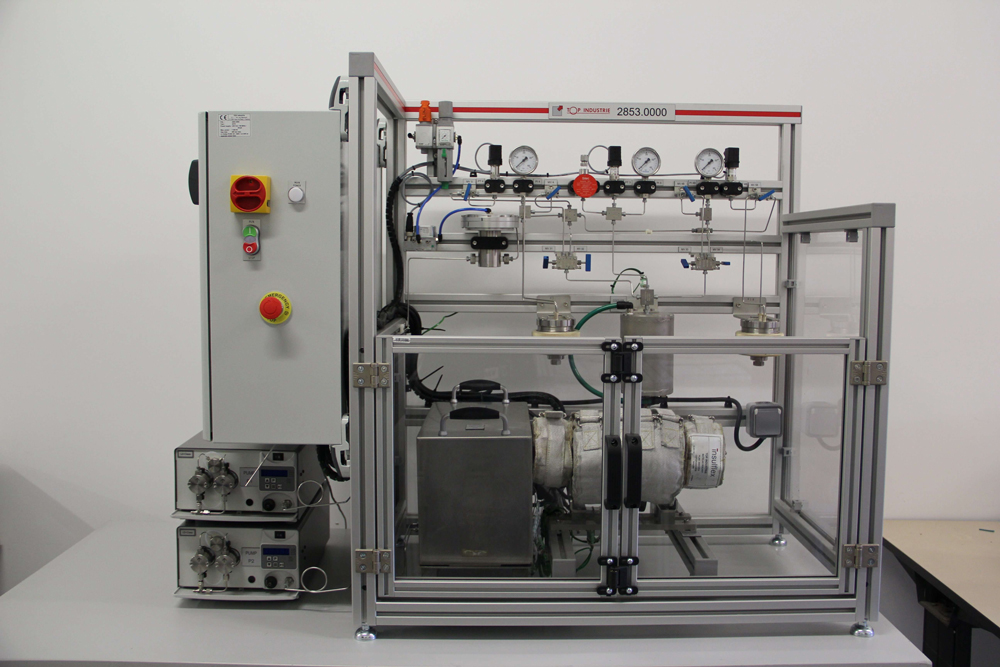

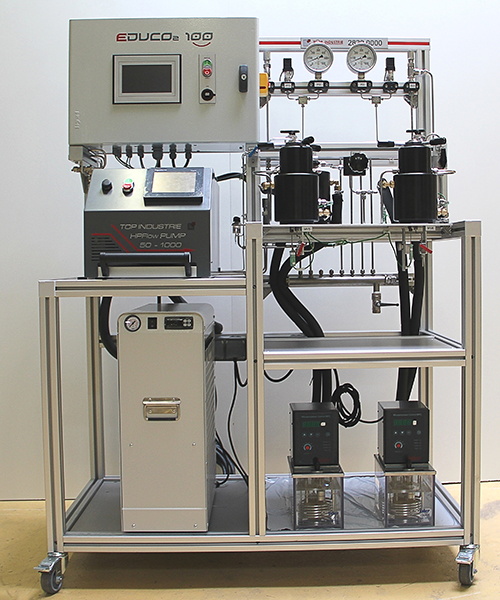

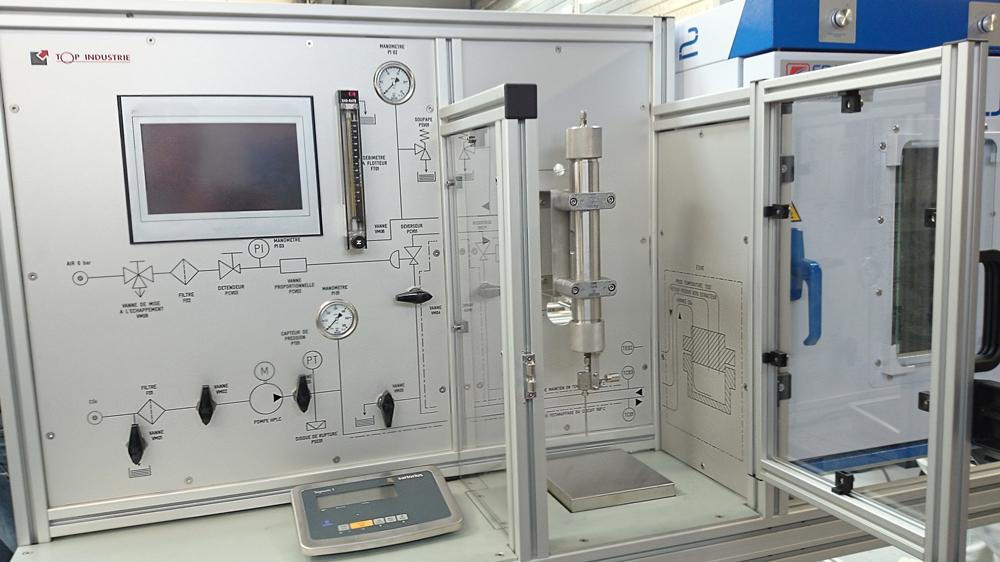

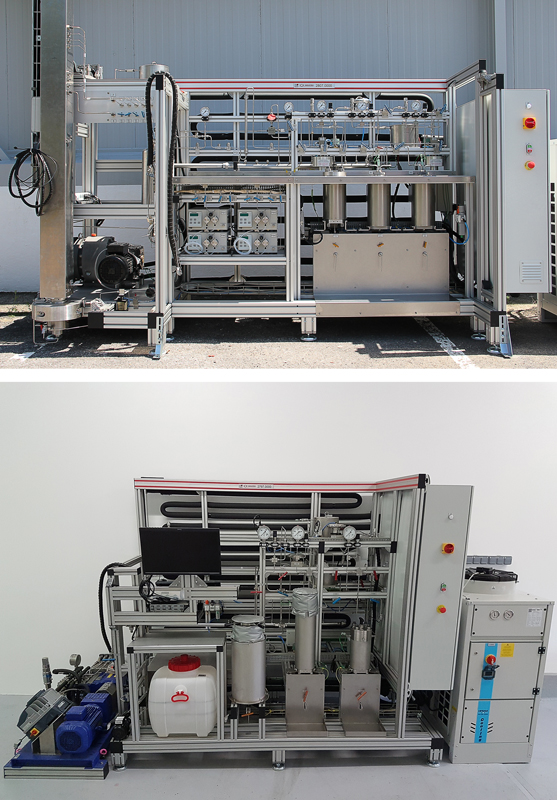

- Pumping modules with different types of pumps, compressors and injection systems

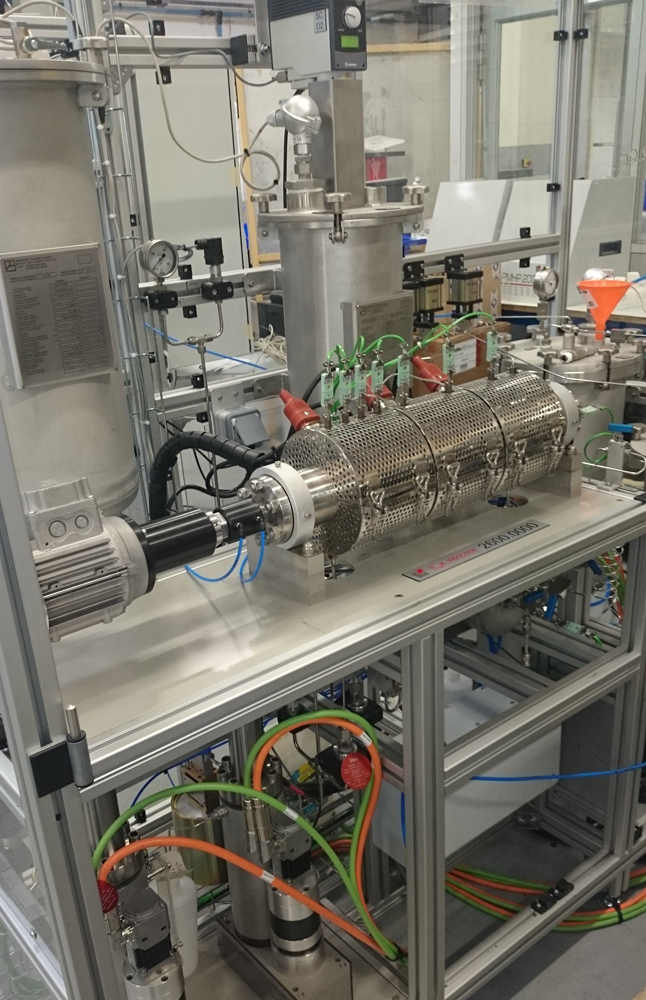

- Autoclaves and reactors designed specifically for your process and application

- Product Collectors, Samplers, Separators and Purification Systems for the production and evaluation of your products

- To meet budgetary and operational requirements, we will be able to adapt our units with many options:

- Adapt mixers, nozzles, specific support and contact devices

- Adapt shapes to your product

- Use different types of autoclave closures for a clean or dangerous environment

- Add instrumentation and analysis equipment

- From 1 to 50 litres (standard 1, 2, 5, 10, 25, 50 litres)

- Working pressure from 5 MPa to 100 MPa

- CO2 pump flow from 6 to 100 Kg/h

- Fractioning unit from 2 à 6 meters

- Heaters, chillers and condensers…

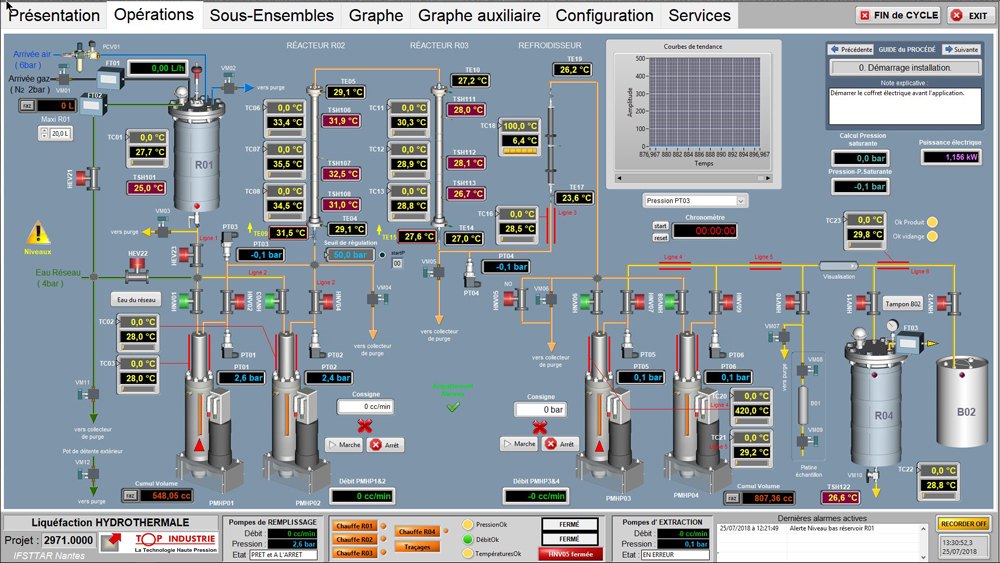

- SCADA with PC or PLC

- Working temperature up to 150°C

- MOC stainless steel or corrosion-resistant alloy.

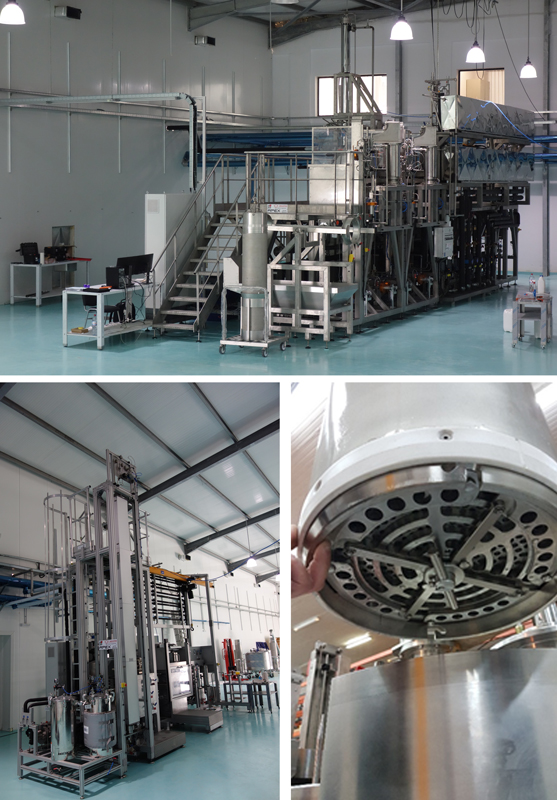

Our pilot plant systems can be design to be very modular and to be adapted to all current supercritical fluid processes like extraction, or liquid fractionation, or both, or even reaction, chromatography, encapsulation and impregnation. For extraction units, we provide extractor with volume from 1 to 50 litres. For fractioning units, we design columns with different heights according to your needs.

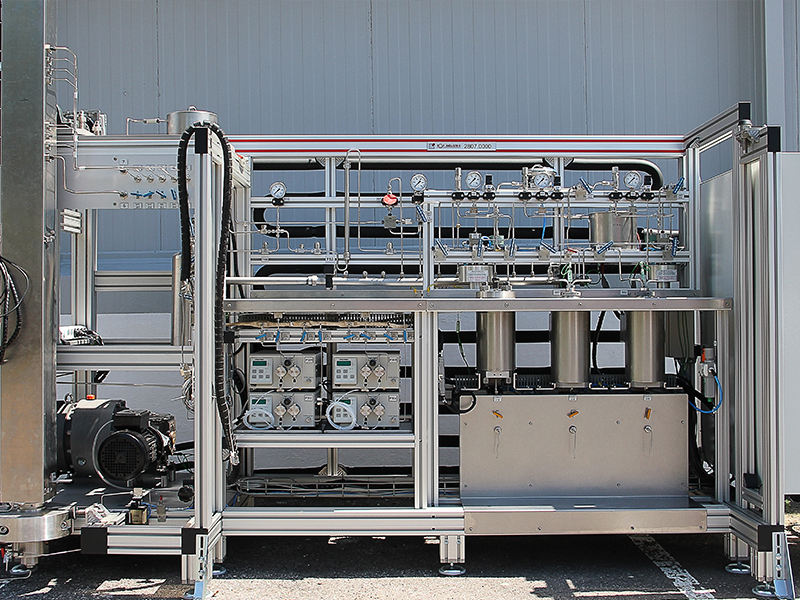

- Heating and cooling equipment, heaters, condensers...

- CO2 storage module.

- CO2 pressurization skid; 300kg/h throughput up to 3 tons/h and pressure up to 700bar.

- Co-solvent pump up to 300kg/h

- Separators, volumes, pressure and adaptable numbers.

- Out filtration system.

- Liquid or steam cleaning systems.

- Handling devices, loading, unpacking...

- Supervision on PC or PLC

- Specific standards, GMP, Atex...

Currently underway: Supercritical Extraction Unit for vegetal products 2 x 565 liters

- Heating and cooling methods, heaters, condensers...

- CO2 storage module, 1600L

- CO2 pressurization skid, 3 tons/h flow and pressure up to 400bar.

- Co-solvent pump 300kg/h

- Separators 200L and 80L.

- Liquid or steam cleaning systems.

- Handling devices, loading, unpacking...

- PLC Supervision

- Atex compliance...