Material test benches

From 1990 Top Industrie started to develop a wide range of specific test benches.Low, medium and especially high-pressure test means (from a few mbar to a few thousand bar).

Tailor-made benches intended for the various actors of the mechanical, aeronautical and military industries, as well as for the development of R&D for the study and qualification of new materials.

- Stamping bench (in service pressure or test pressure)

- Bench of bursting, cycling, aging.

- Leak test bench.

- Bench for the qualification of seals and sealing materials, Rapid Gas Decompression...

- Pressure equipment calibration bench.

- Bench for deformation under pressure.

- Combined pressure and temperature test bench.

We can help you to develop your equipment, your materials, your systems; by offering you solutions perfectly adapted to your needs, test means and custom test benches combining performance and safety.

They trust us

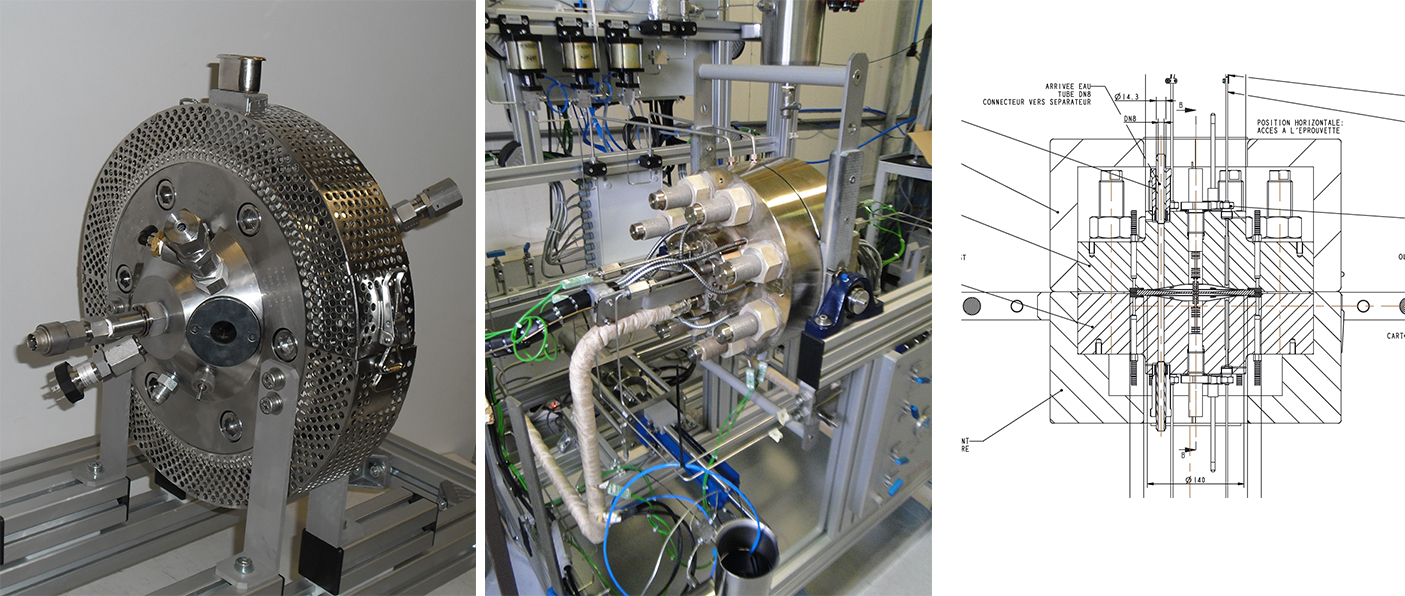

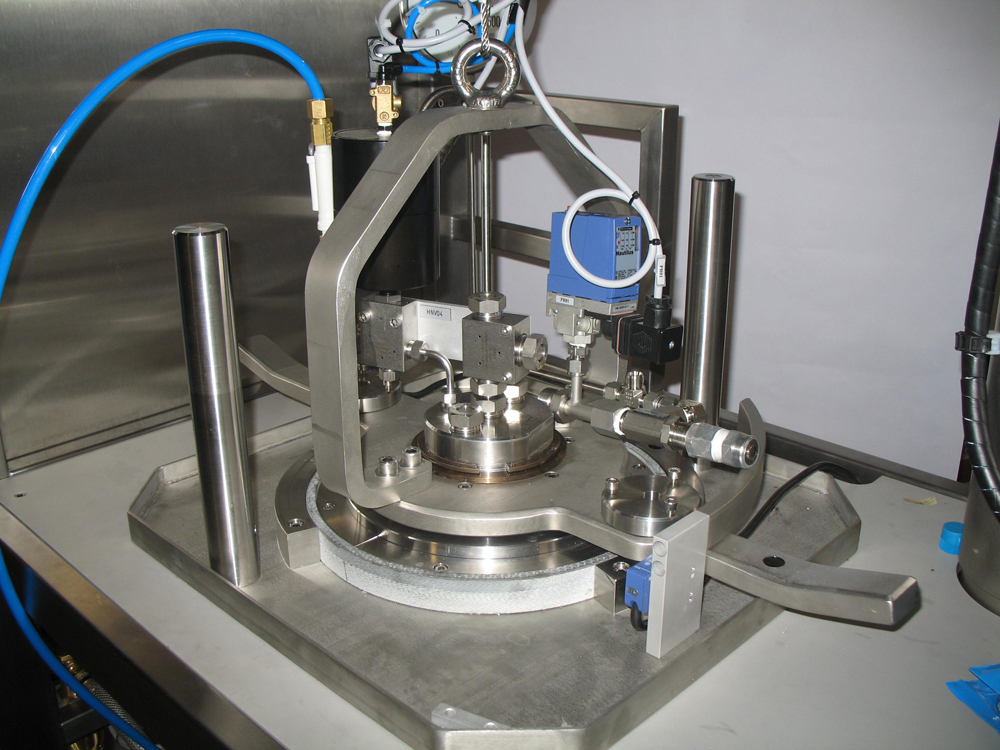

Equibiaxial test cell on stainless steel membrane.

Stress corrosion study cell for the ageing of metallic membrane under alternating pressure in PWR conditions.- Test pressure 200 bar

- Ambient temperature up to 360°C.

- Number of cycles up to 106

- Crack detection

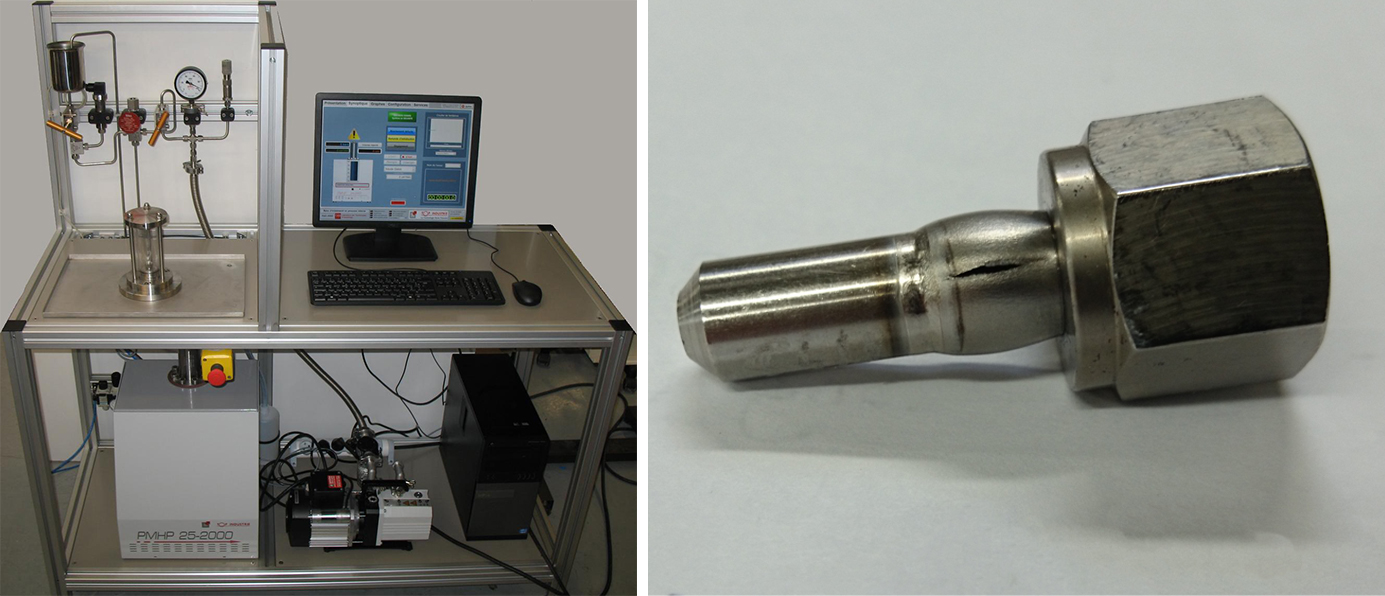

Bench for bursting test on nuclear fuel tube weld.

Test bench for the approval of welding processes developed by the CEA for the sealing of fuel tubes.- Test pressure up to 2000bar

- Ambient temperature.

- Pressurization with motorized pump Top Industrie

- PMHP 25-2000bar

- Control developed under LabVIEW

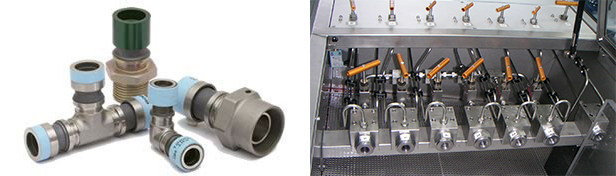

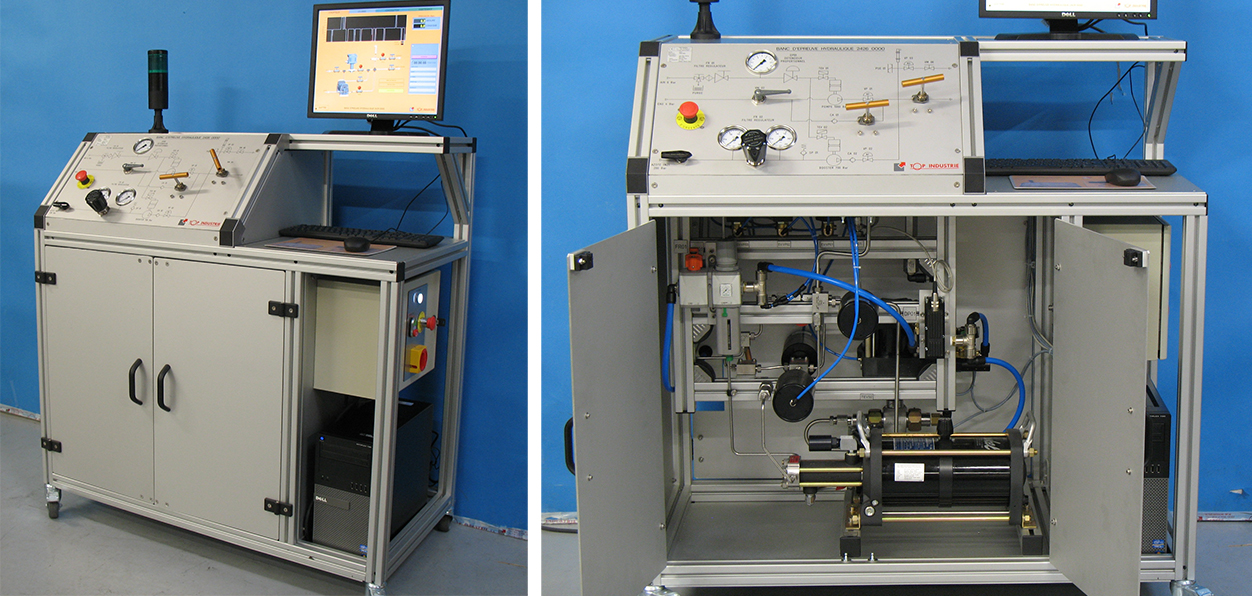

Leak and burst test bench for aeronautical fittings

- Water / oil generator group 1000 bar & burst 4000 bar

- Semi-automatic test bench for dielectric connections

- Tests on tubes Ø 1/4˝à 3/4˝

- LabVIEW automation and supervision

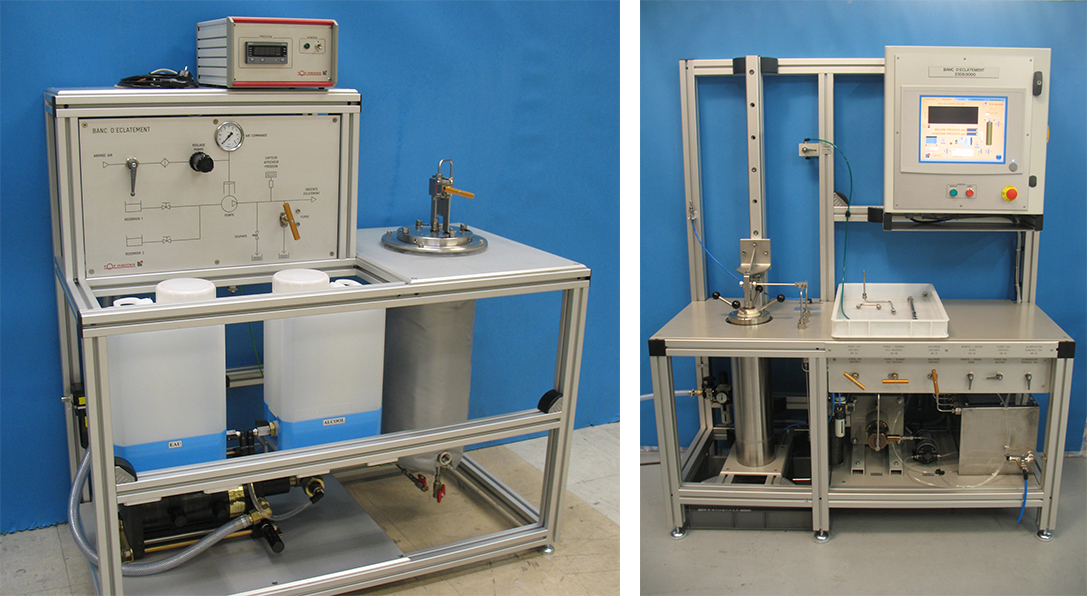

Leak and burst test bench for tubes or hoses.

- Gas generation unit 700 bar/ water 1500 bar

- Testing of flexible hoses for civil aeronautics

- Complete automation and safety.

Test bench for tube bursting, internal pressure and collapse

- Liquid generation unit; water 2500 bar

- Tube dimensions: 1/4˝jusqu'à 2˝

- Bursting chamber 2500 bar

- Automation and control

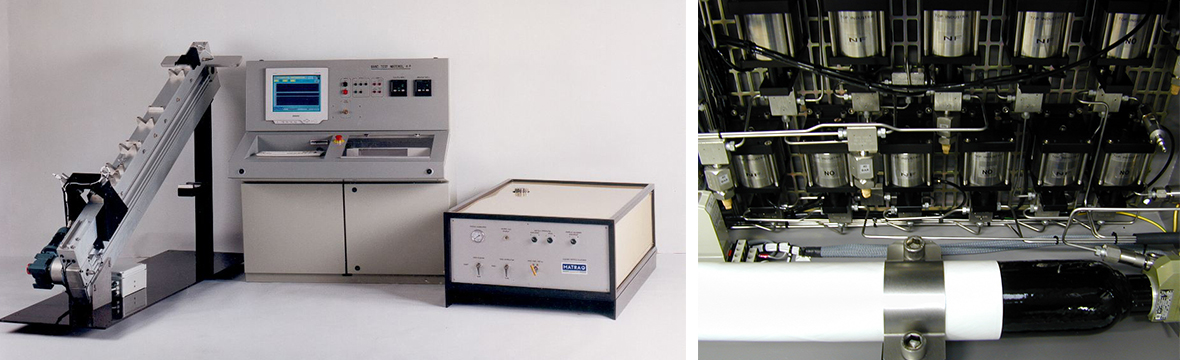

Stamping bench, deformation and bursting measurement

Tests of composite & metallic tanks for military aeronautics.

- Pressure 0 - 4000 bar

- Automated measurement of stress, expansion and biaxial deformations

- Generating unit with hydropneumatic pumps.

- LabVIEW supervision with fast acquisition system.

Qualification bench and leak test for Offshore seals

- Test pressure: 1700bar

- Test temperature: -110°C / 250°C

- Fluid; liquid or gas

- Mixed air-conditioned liquid nitrogen & resistive heating chamber

- Pressure generating unit with hydro-pneumatic pump 2000bar and Gas 2000bar multiplier

- Climb and descent slope control, Rapid Gas Decompression.

- Cycling in pressure and/or temperature.

- Piloting with LabVIEW supervision developed by Top Industrie

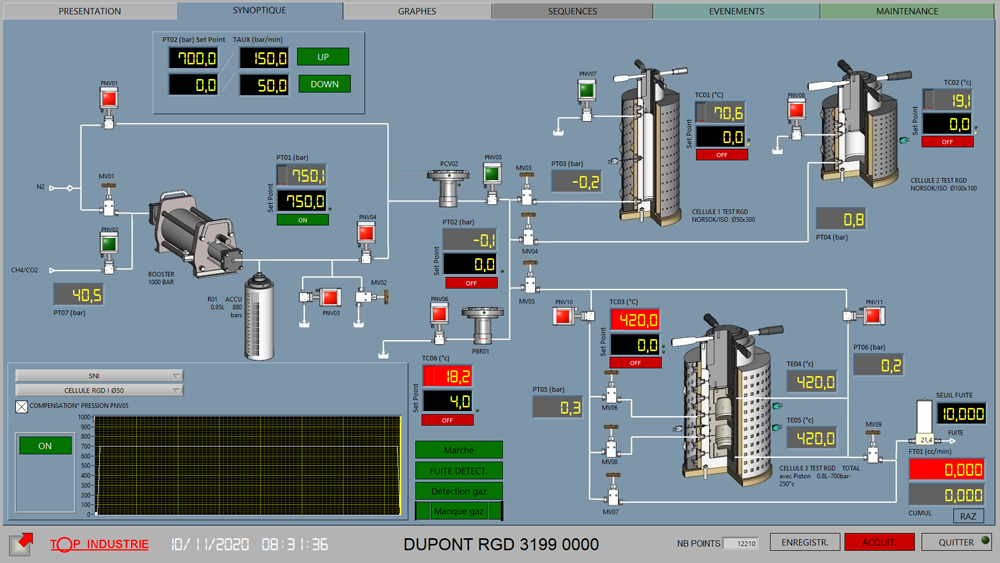

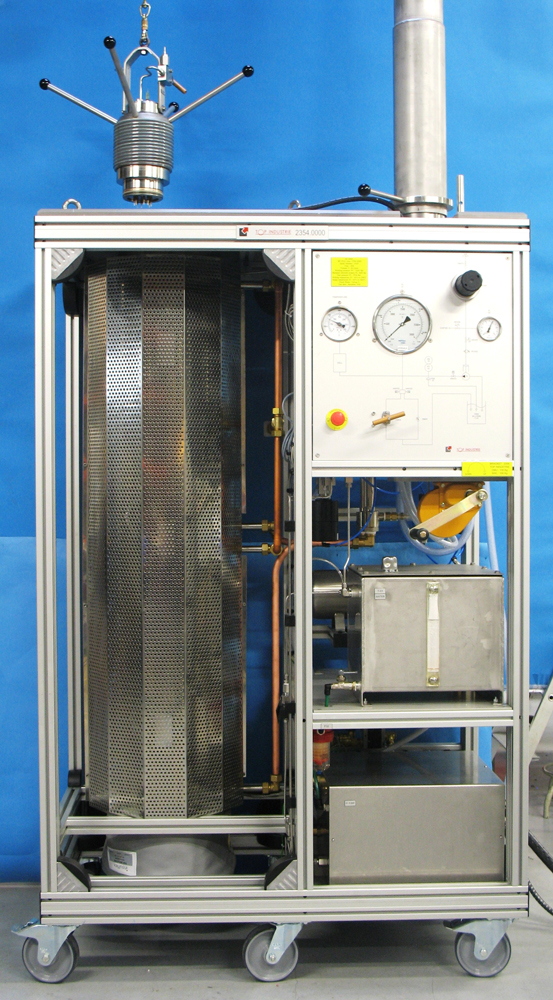

RGD (Rapid Gas Decompression) test bench for elastomer seals

These test benches are intended for the study of the behavior of elastomer seals, subjected to alternating pressurization and decompression stresses in severe pressure and temperature conditions and for any physicochemical medium.

- Sample type: O-Ring AS568 - #349 // O-Ring AS568 - #425

- Type of gas: N2 - CO2/CH4 - CO2/N2 - Various premixes.

- Working pressure 190 to 700bar

- RGD test type: Total GS EP PVV154 // ISO 23936 // Norsok M710

- Decompression rate 10 to 127bar/min.

Test and calibration bench in well conditions ˝Well Testing ˝

These test benches are intended for the study of the behavior of components and tools, for the qualification and calibration of equipment in HP/HT° environment in well conditions during the drilling or exploitation of oil industries..

- WT measurement means, pressure, flow, temperature, US measurement sensors, fiber optic sensors...

- Motor systems, pumps and fluid circuit elements.

- Validation of embedded electronic boards.

- Well simulator

- Cementing studies

- Operating pressure: 10, 20, 30, 40 kPsi (700 to 3000bar)

- Fluid: water, oil, sludge...

- Operating temperature: -20 to 250°C.

- Equipment and options :

- Sealed, multi-contact electrical bushings

- Coaxial electrical bushings for US measurement.

- Pressure generation unit.

Equipment and options :

- Waterproof electrical bushings, multi-contact

- Coaxial electrical bushings for US measurement.

- Pressure generation unit.

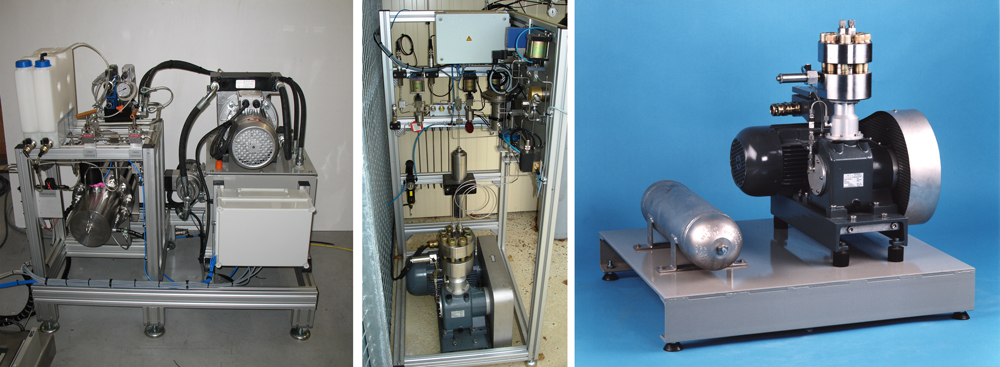

Pressure generation benches made to measure :

Gas pressure generation unit from 200 to 3500 bar.

- Pneumatic or electric diaphragm blower

- Booster Group.

- Nitrogen, Helium, Hydrogen, Argon, Oxygen...

- Complete automation and safety.

Liquid pressure generating unit from 100 to 7000bar.

- Hydropneumatic pump up to 4000bar

- High pressure motorized pump

- Pressure intensifier up to 7000bar